Platinum

99.99% Platinum sputtering targets. 110% commitment.

What does it take to design and manufacture the world’s most innovative and reliable platinum sputtering targets and evaporation pellets? It starts with a rare dedication to one of the Earth’s rarest metals. Including a team of precious metal experts with over a century of experience standing behind every platinum sputtering target and evaporation pellet we make.

Why is platinum uniquely suited for sputtering targets?

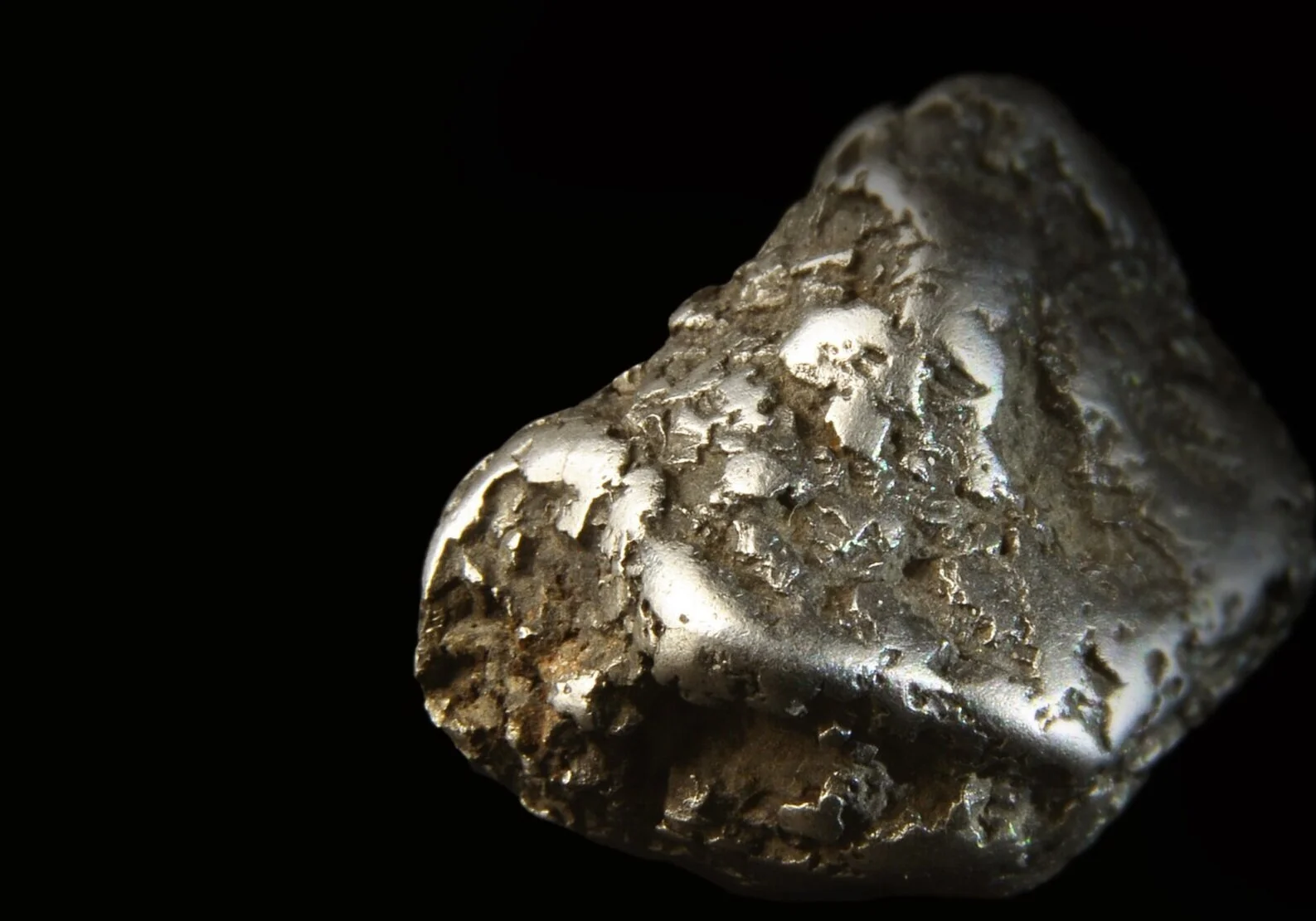

Platinum is one of the rarest elements in the Earth’s crust. It is a radiant, silvery-white metal whose resemblance is similar to fellow platinum group metal, palladium. It is malleable, ductile and highly resistant to corrosion - it does not oxidize in air at any temperature. Its unique properties make platinum sputtering targets ideal for manufacturing semiconductors, fuel cells, batteries, surgical instruments, laboratory instruments, CD-ROMs, flat panel displays, optical storage devices and optical communications equipment. Along with palladium its most common commercial use is in catalytic converters for the automotive industry.

Helping customers develop a more efficient platinum sputtering process.

DHF Technical Products specializes in platinum and precious metal sputter targets. Platinum sputtering occurs under highly controlled conditions and our platinum targets are made for your individual coaters and their exacting specifications. We manufacture parts to have an optimal grain size and density. The result is a custom platinum sputtering target that helps you apply metal as efficiently and cost-effectively as possible to nearly any substrate.

Custom designed and manufactured platinum sputtering targets.

Our innovative platinum targets are designed and manufactured in custom diameters, custom shapes, custom thicknesses and custom purities up to 99.99%. We produce one-of-a-kind designs and materials for both planar and rotary targets. DHF platinum targets are custom made, bespoke and designed to fit your coater to produce the most efficient sputtering outcome possible. Each custom platinum target is manufactured in our ISO-9001-2015 factory in Rio Rancho, New Mexico and analyzed using industry standard techniques including X-Ray Fluorescence (XFR) and Inductively Coupled Plasma (ICP).

Lowering platinum sputtering target cost of ownership.

Let DHF Technical Products reimagine your platinum sputter targets from beginning to end to lower the cost of sputtering target ownership. We offer full lifecycle support from design and manufacturing to shield cleaning and spent target refining/recycling. Everything we do is designed to help extend the life of your platinum sputter targets and reduce your long term costs.

Working capital solutions from the platinum sputtering target experts.

Our state-of-the-art R&D group can help identify designs and materials to optimize your platinum sputter coating performance. The precious metal sputtering target experts at DHF Technical Products can help you manage your precious metal spend so you can keep more of your working capital and increase cash flow.

Clean air initiatives and the demand for platinum.

The global expansion of cars and trucks has resulted in increasing demand for platinum and palladium in catalytic converters to help eliminate harmful emissions from combustion engines. Russia has one of the world’s largest reserves of palladium. As such, the demand and prices for palladium have seen fluctuations in the 21st century. Platinum has experienced similar volatility as well.

At DHF Technical Products, our specialty is helping platinum and precious metal sputtering target customers secure a steady, high-quality supply of critical materials during turbulent metal markets. If your manufacturing process depends on platinum sputtering targets, now is a good time to reevaluate your future needs. Or, as we like to say, “Let’s talk targets.”

For those who enjoy their sputtering targets like a good steak. Rare.

Everyone from carnivores to vegans can appreciate our one-of-a-kind platinum sputtering targets. Each one is custom designed with the goal of putting more metal on the substrate and keeping more of your working capital working harder for you. That includes a target recycling program that uses DHF state-of-the-art analysis methods to credit your spent platinum targets and quickly turn them into new ones. For those who prefer their rare targets, well done.

Platinum sputtering target applications.

Thin films of platinum are often used to manufacture semiconductor chips, CD-ROMs, flat panel displays, optical storage devices and communications equipment, surgical instruments, lab instruments, sensors and more.

Medical Devices.

Tiny amounts of platinum from a sputtering target play an important role in antibiotic coating for surgical instruments, life-support devices and other medical electronics equipment. The fast-growing point-of-care test industry uses precious metal sputtering targets including platinum for innovative diagnostic tests, like blood glucose monitoring products, which are helping people get accurate, life-saving test results in minutes.

Aerospace.

The corrosion resistant properties of platinum make it a useful element in a variety of aerospace applications and next generation inventions. Platinum sputtering deposition has helped create new possibilities and products to help explore space.

Automotive.

Platinum’s properties make it an ideal element for a number of state-of-the-art automotive applications. Thin films of platinum are often used as a corrosion resistant connector.

Semiconductor Chip Manufacturing.

Semiconductor chips often use high purity platinum sputtering targets. Requirements can range from 99.99% (4 nines or 4N) and 99.999% (5 nines or 5N) purity which are generally higher than requirements for products like solar cells or flat-panel displays.

Sensors.

A thin film of platinum deposited by a sputtering target may be found in a variety of sensors manufactured by the aerospace, automotive and medical industries to name a few.

Optical coatings.

Platinum sputter coatings can be used for a variety of optical products including CD-ROMs, eyeglasses, sunglasses, vehicle headlights, mirrors and windows. This includes optical coatings for data storage and communications as well as optical filters in the field of laser technology.

Flat Panel Displays.

Thin films of platinum from a sputtering target are often used to manufacture flat panel displays.

Call us when you want your evaporation pellets to go platinum.

DHF evaporation pellets combine 99.99% pure platinum with pure innovation to break records for efficiency. Our expertise in precious metal refining and reclaiming helps maximize your precious metal investment, tie up less working capital and credit your spent pellets, fast. Who doesn’t like the sound of that?